What is Industrial Pipe Insulation?

- RayBraun

- Mar 27, 2023

- 3 min read

Updated: Sep 12, 2023

Industrial pipe insulation is a crucial aspect of modern industrial applications that plays an essential role in conserving energy, enhancing efficiency, and protecting both workers and the environment. In industries such as oil and gas, chemical, power generation, hot mix asphalt, and food processing, pipe insulation is vital in maintaining process stability and ensuring optimal performance. We will cover the purpose, types, benefits, and importance of industrial pipe insulation to provide a comprehensive understanding of this often overlooked, yet indispensable component in the industrial sector.

The Purpose of Industrial Pipe Insulation

Energy conservation: Insulating industrial pipes reduces heat loss, leading to significant energy savings. This not only lowers operational costs but also helps industries meet energy efficiency targets.

Temperature control: Maintaining specific temperatures is often essential for different industrial processes. Pipe insulation helps regulate temperature, ensuring that fluids or gases within the pipes remain at the required temperature.

Safety: High-temperature pipes can pose a danger to personnel working near them. Insulation can minimize the risk of burns or injuries, thereby enhancing overall safety within the facility.

Noise reduction: Industrial processes can generate considerable noise, which can be detrimental to worker health and productivity. Insulating pipes can reduce noise levels by limiting the transmission of vibrations through the pipes.

Condensation control: Insulation can prevent the formation of condensation on cold pipes, which can lead to corrosion, equipment failure, and safety hazards.

Environmental protection: Insulating pipes can reduce the emission of greenhouse gases and minimize the environmental impact of industrial operations.

Types of Industrial Pipe Insulation Materials

Mineral wool: Made from molten rock or slag, mineral wool provides excellent thermal insulation and is resistant to high temperatures. It is also highly durable, non-combustible, and water repellent.

Fiberglass: Consists of extremely fine glass fibers and is one of the most ubiquitous insulation materials. It's commonly used in many different forms of insulation: blanket (batts and rolls), loose-fill, and is also available as rigid boards and duct insulation.

Calcium silicate: A rigid, high-density material, calcium silicate offers excellent thermal performance and is particularly suitable for high-temperature applications. It is also non-combustible, resistant to moisture, and provides excellent structural support.

Cellular glass: Comprising millions of sealed glass cells, cellular glass insulation is a lightweight, non-combustible material that provides good thermal performance and excellent resistance to moisture and chemicals.

Polyurethane and polyisocyanurate foam: These closed-cell foam materials offer excellent thermal insulation properties and are lightweight, easy to install, and resistant to moisture. They are particularly suitable for low-temperature applications.

Elastomeric foam: A flexible, closed-cell material, elastomeric foam is ideal for insulating irregularly shaped or hard-to-reach pipes. It provides good thermal insulation, is resistant to moisture and chemicals, and has excellent noise reduction properties.

Aerogel: Composed of over 90% air, aerogel is a lightweight, high-performance insulation material that offers exceptional thermal performance, even at high temperatures. It is also hydrophobic, non-combustible, and resistant to chemicals.

Improved efficiency: Insulated pipes minimize heat loss, ensuring that the energy required for heating or cooling is used effectively, thus boosting overall process efficiency.

Reduced operational costs: Lower energy consumption due to insulation leads to reduced operational costs, providing a competitive edge in the market.

Extended equipment life: Insulation helps protect pipes from corrosion, condensation, and mechanical damage, prolonging their lifespan and reducing maintenance costs.

Enhanced safety: Insulated pipes reduce the risk of burns or injuries, fostering a safer work environment and minimizing potential liabilities.

Environmental stewardship: By conserving energy and reducing greenhouse gas emissions, industries can actively

At ERS Insulation, we believe in providing insulation solutions that will reduce your energy costs. We’ve been saving our customers money since 2010. Our skilled team of pipe insulation contractors are available to install at your facility if it’s located in the Northeast or Midwest of the USA. We service the states of Ohio, Indiana, Michigan, Kentucky, Pennsylvania, Virginia, West Virginia, New York, and New Jersey.

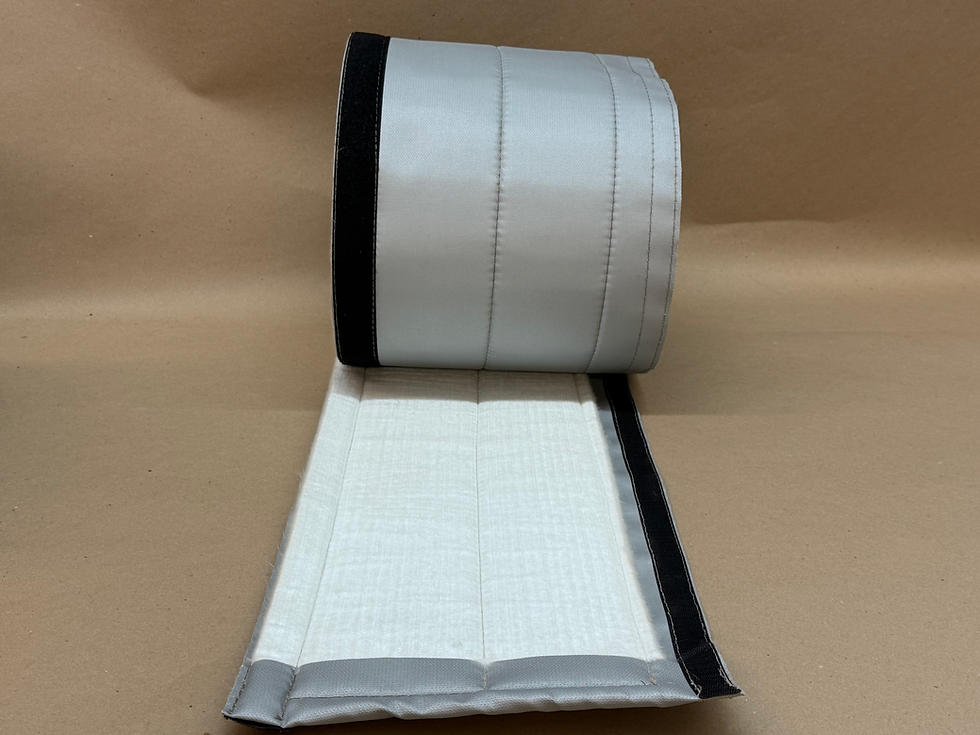

Our blanket insulation called “ERS Wrap” is made of fiberglass and can be used to insulate almost any hot mechanical component. With fiberglass pipe insulation, generally in 9 months, you will see the return on your investment of insulating your mechanical equipment because your energy costs will go down significantly.

About Ray Braun, Founder of ERS Insulation:

Ray has been in the industrial insulation business for over 40 years. After going to many plants and facilities, Ray noticed just how many hot mechanical parts were left uninsulated. He knew he could make something better than the traditional products on the market.

Comments